Electrical Safety

Electrical Fires

Electrical Fires

When you buy electrical equipment do you ever consider Fire Safety and the causes of Electrical Fires? Do you ask the question what is the most likely cause for a fire starting in the workplace? This might be an easy question to answer if you are carrying out activities where sources of ignition are common. Examples include welding, grinding, plumbing, glass-blowing or any other “hot works”. However what should you be looking for if there are no obvious sources? The HSE gives good advice on what to look for here: HSE Fire Safety

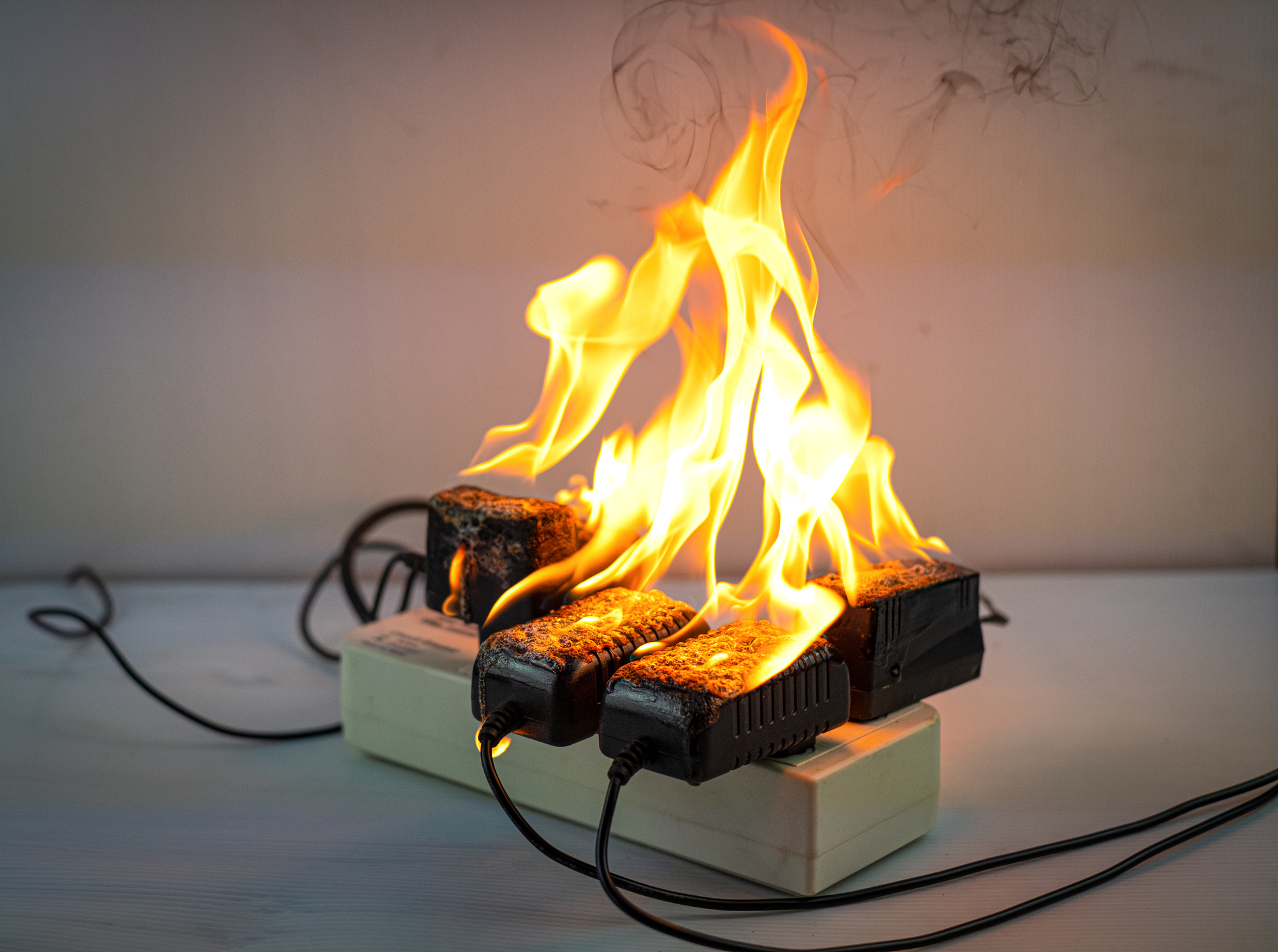

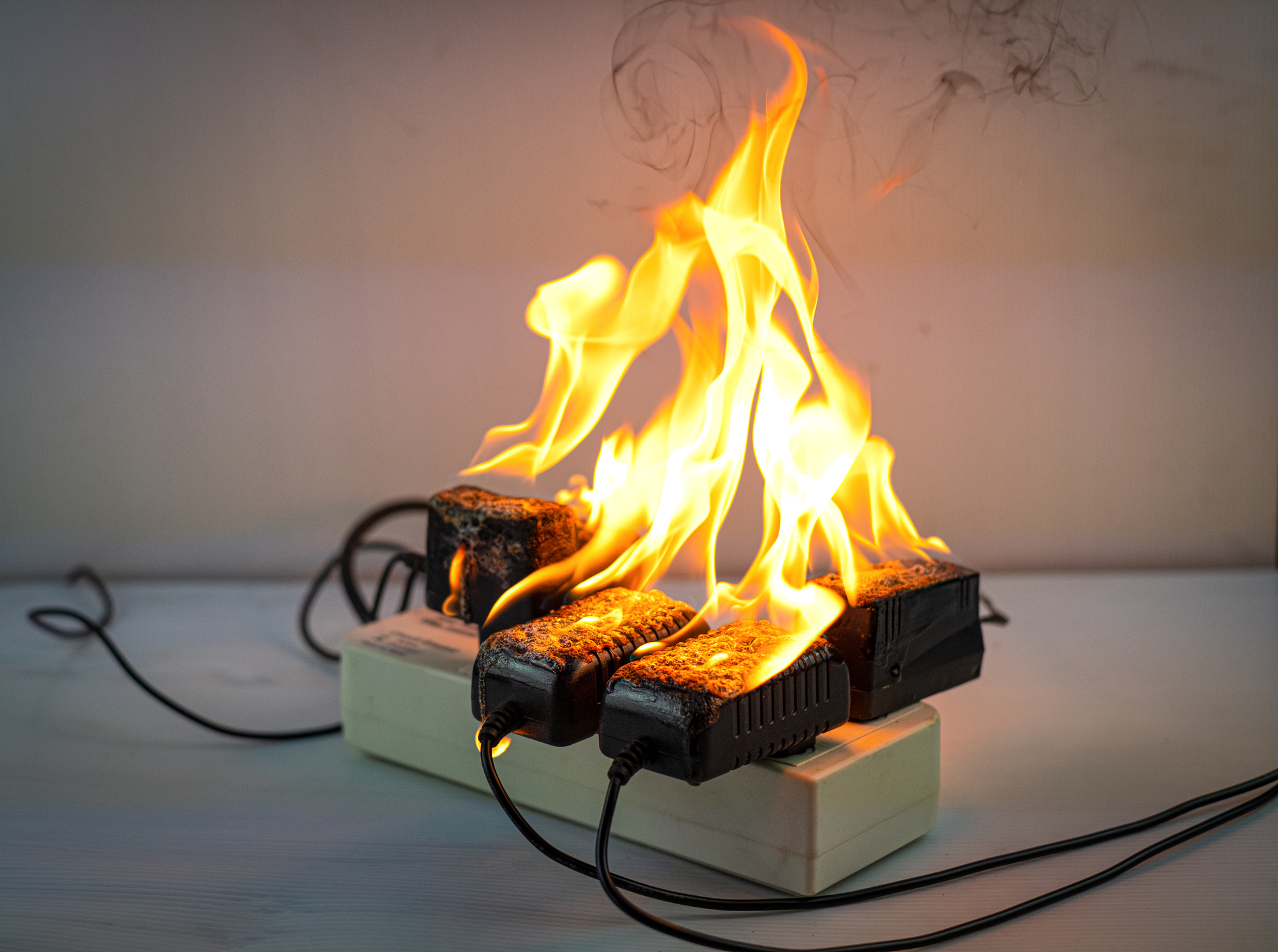

Beware of counterfeit, non-branded or non-compliant equipment causing Electrical Fires

There has been a huge influx of cheap electrical equipment that does not meet UK or EU standards and much of this has a fire safety implication. In particular, non-original phone chargers are regularly overheating and catching fire or, in some cases, exploding. Remember that all electrical equipment brought into the workplace is subject to the same controls set out by the organisation. That will include checking and testing using a PAT (portable appliance test), along with company owned items.

Portable heaters

Another principal cause of electrical fires are portable electric heaters. Again these are often cheap items that do not meet acceptable standards and are prone to failure with serious results. Even if good quality heaters are in use, there is a risk of materials being placed too close to them and catching fire. A good example is the covering of heaters to dry clothing.

Oil-filled heaters are a better alternative and reduce the risks considerably, but you still need to be careful where you plug them in.

Fixed electrical wiring

Another consideration, especially in older buildings, is to think about the fixed wiring that forms the electrical system throughout the building. This may in many cases be the original wiring as installed several years or even decades before and this can be a potential fire safety hazard. In general, if is hasn’t been disturbed it will continue to perform without danger, but sometimes there are issues with the old insulation around wires becoming brittle or even reacting with the plaster on walls where it runs to switches or sockets.

The usual way to test this is to have an Electrical Installation Condition Report carried out which will check consumer units, protective bonding, lighting, switches and sockets etc. This is normally every 5 years for workplace settings.

Electrical Fires caused by faults

Faulty electrical equipment and wiring is responsible for many fires and is unusual in that ignition can occur without warning or when no-one is on the premises, such as night-time.

For these reasons it is advisable to keep everything in good order and checked by qualified, competent electricians. That’s important – electricity can and does kill!